Based on the PETamentor design, the Pulltrusion Machine emphasizes efficient heating and a controlled puller system. Key development milestones:

- Prototype Frame: Built from aluminum profiles to maintain alignment between cutter, heater, and puller assemblies.

- Cutter Mechanism: Designed a rotary cutter to slice bottles into uniform ribbons for consistent melting.

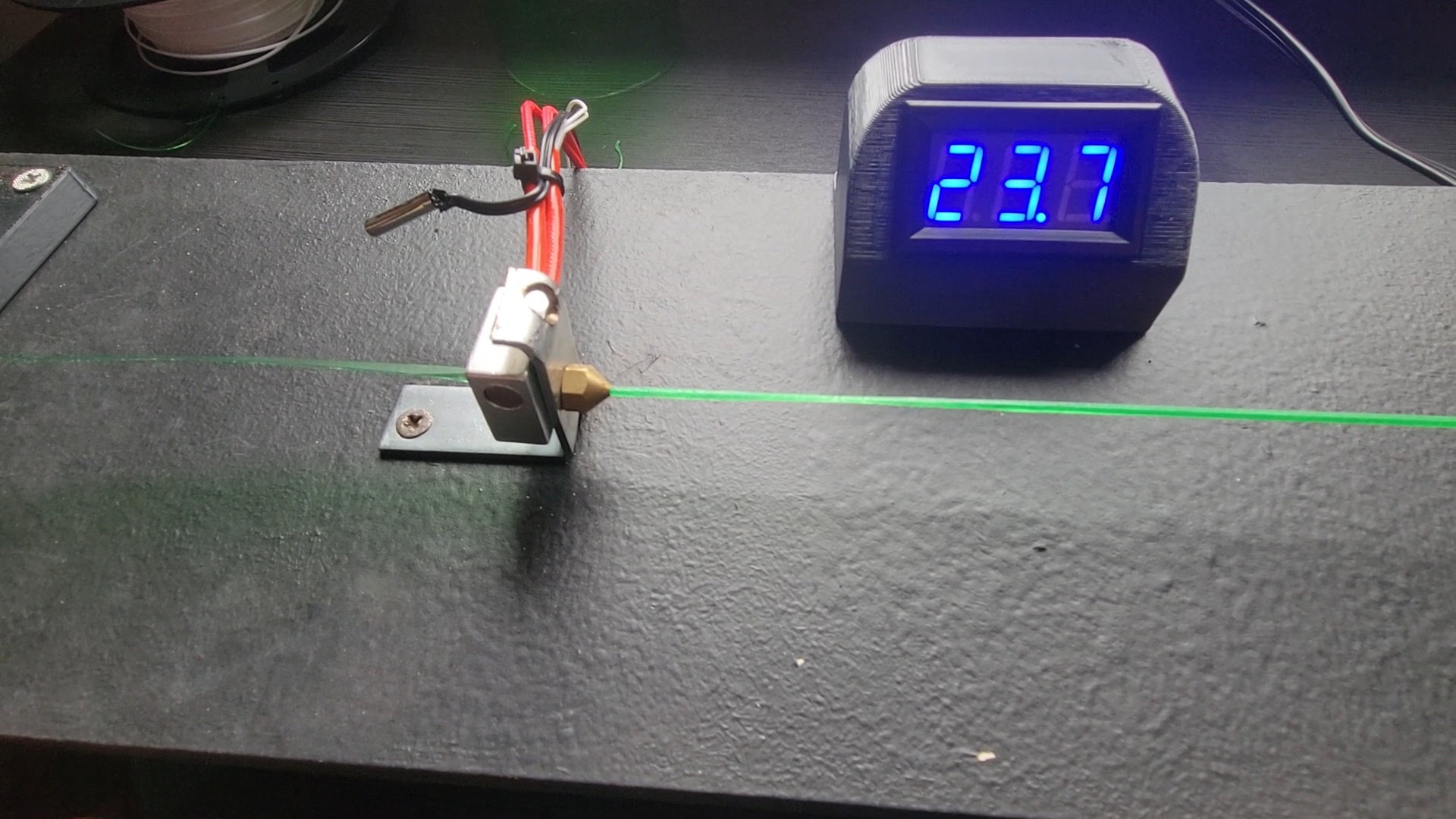

- Nozzle & Heater: Tested optimal filament diameter of 1.75 mm, optimizing heater cartridge placement for uniform temperature.

- Puller Calibration: Iterated on motor speeds using a JGB37-520 high torque geared motor with 7 rpm.

- Temperature Control: Integrated a W1209 digital controller to maintain nozzle temperature between 240 °C and 260 °C. This was later upgraded to a W3230 for more accurate control and temperature display.

Challenges & Solutions:

- Uneven Ribbon Thickness: Early tests yielded inconsistent ribbon width; refined blade angle and guiding channel to ensure uniform strips.

- Nozzle Clogging: PET caramelized at high temperatures; optimized feed rate and added a short cooling zone before the puller.

- Puller Slip: Initial wheels lacked traction; switched to toothed rollers to eliminate slippage.